ABDT-LZT series plastic rotameter has the characteristics of simple structure, light weight, corrosion resistance, not easy to break, non-toxic and tasteless, easy to use and so on. It is mainly used in chemical industry, light industry, medicine, food, environmental protection and other departments to measure the flow of single-phase non pulsating flow of liquid.

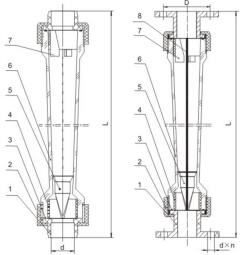

Structure and outline drawing

Flowmeter structure: It is mainly composed of transparent plastic cone tube with small end downward and large end upward, float that can move up and down in the cone tube, nut, connection pipe, guide rod, stop shaft, etc.

The outline is shown in the figure: it is mainly divided into short tube type and long tube type. According to the connection method, it also has plug-in pipe connection, thread connection and flange connection.

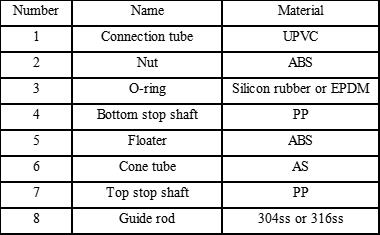

Parts and material:

Note: (1)The conventional joint is UPVC engineering plastic sink connection,

(2)Under special circumstances, the guide rod can be F46 lined with 304 stainless steel.

(3) "O" ring can also be fluororubber, etc.

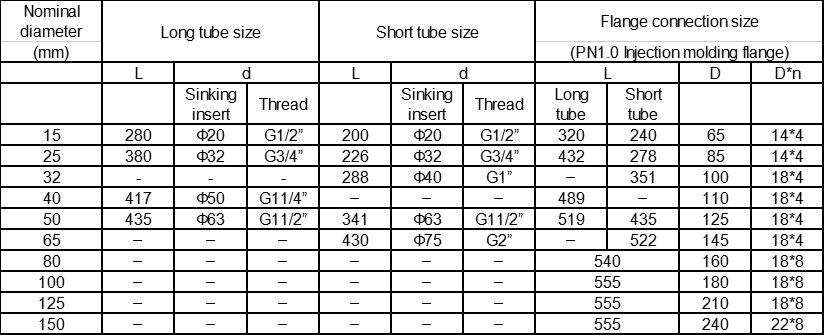

Installation dimension

Note:(1)The above are conventional flow and special flow needs customization.

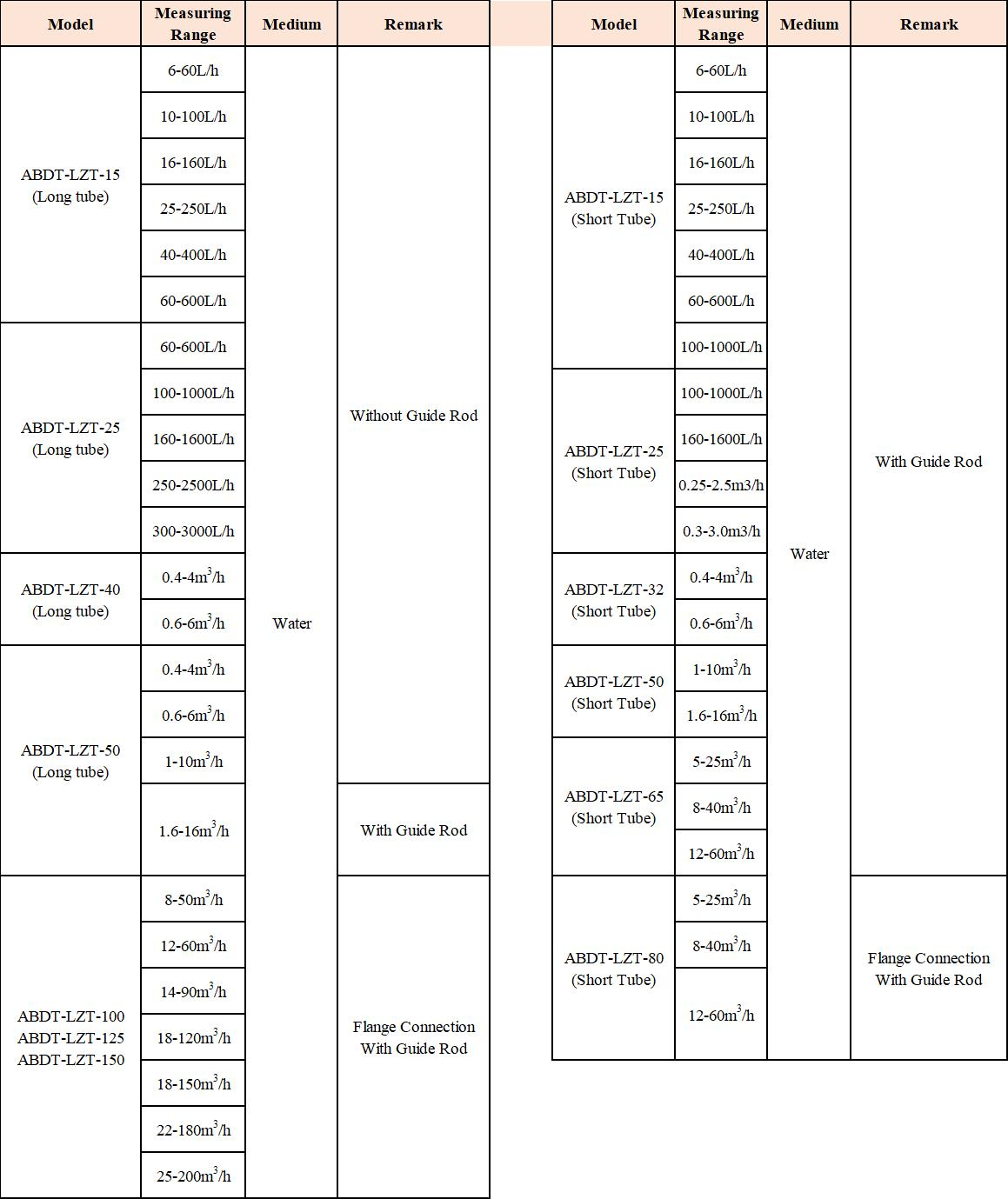

Specification and model

Installation and precautions

(1) Before installation, first disassemble the outlet connecting pipes of the flowmeter to remove the foam or the plastic pipe supports in the instrument, then assemble the connecting pipes in the flowmeter.

Note: The O-ring seal shall be installed in the grooves of the connecting pipes to prevent water leakage in reassembling the connecting pipes.

(2)The matched (ABS or PVC) plastic pipe can be used for the flowmeter interface by glue connection. It can also be connected with plastic flange first and then metal flange.

(3)The flowmeter must be installed vertically with an appropriate height convenient for float reading(the included angle between the center of the flowmeter and the plumb line shall not exceed 5°), and the sight shall be parallel to the reading position of the float when reading.

(4)The straight sections for the upstream and downstream inlet and outlet of the flowmeter shall be greater than or equal to 5 times the nominal diameter of the flowmeter.

(5)A filter shall be installed at the upstream of the flowmeter, if the measured fluid contains large particle impurities or dirt.

(6)If the measured fluid is the pulsating flow, and the normal measurement can not be carried out due to the float up and down, the buffer and point setter with suitable sizes shall be installed at the upstream of the flowmeter.

(7)Try to use the optimum flow section of the flowmeter to test the flow (the optimum flow section generally refers to 40%-70% of the maximum flow).

Scan

QR code on WeChat Follow us

Scan

QR code on WeChat Follow us

24-H hotline+86-536-7393118

Mobile phone+86-19953631088

Copyright (©) 2021 Weifang Aobo Instrument Technology Development Co.,Ltd Address:Building 4C, No. 8009, Minzhu street, Hanting District, Weifang City, Shandong Province (Hanting high tech Industrial Park) Record No:鲁ICP备2020035458号-5