Product Features

· Digital smart chip, all-temperature linear temperature compensation;

· Compact structure, compact, cost-effective, multi-connection forms;

· Shock, vibration, stable performance;

Adopt international advanced technology imported sensors.

Application

Widely used in air compressors, hydraulic equipment, machine tools, central air conditioning, refrigeration equipment, water treatment works, environmental purification, hydraulic and pneumatic control engineering, automotive, electrical, chemical, pharmaceutical, food and so on. Old-fashioned pressure equipment replacement essential products.

Technical Data

Specifications:

1. Output: 4ma ~ 20ma, (1 ~ 5v)

2. Power Supply: Dc 24v (12v ~ 32v)

3. Accuracy: ± 0.5% □ ± 1% □

4. Media Temperature: -20 ℃ ~ 85 ℃

5. Ambient Temperature: -20 ℃ ~ 85 ℃

6. Response Time: ≤ 200ms

7. Load: Current Type ≤ 500Ω (Dc 24v Power Supply)

8. Repeatability: ± 0.2% F · S

9. Long Term Stability: ± 0.5% F · S / Y

10. Non-linear: ± 0.2% F · S

11. Temperature Compensation Range: 0 ℃ ~ 60 ℃

12. Overload Pressure: 2 Times The Range

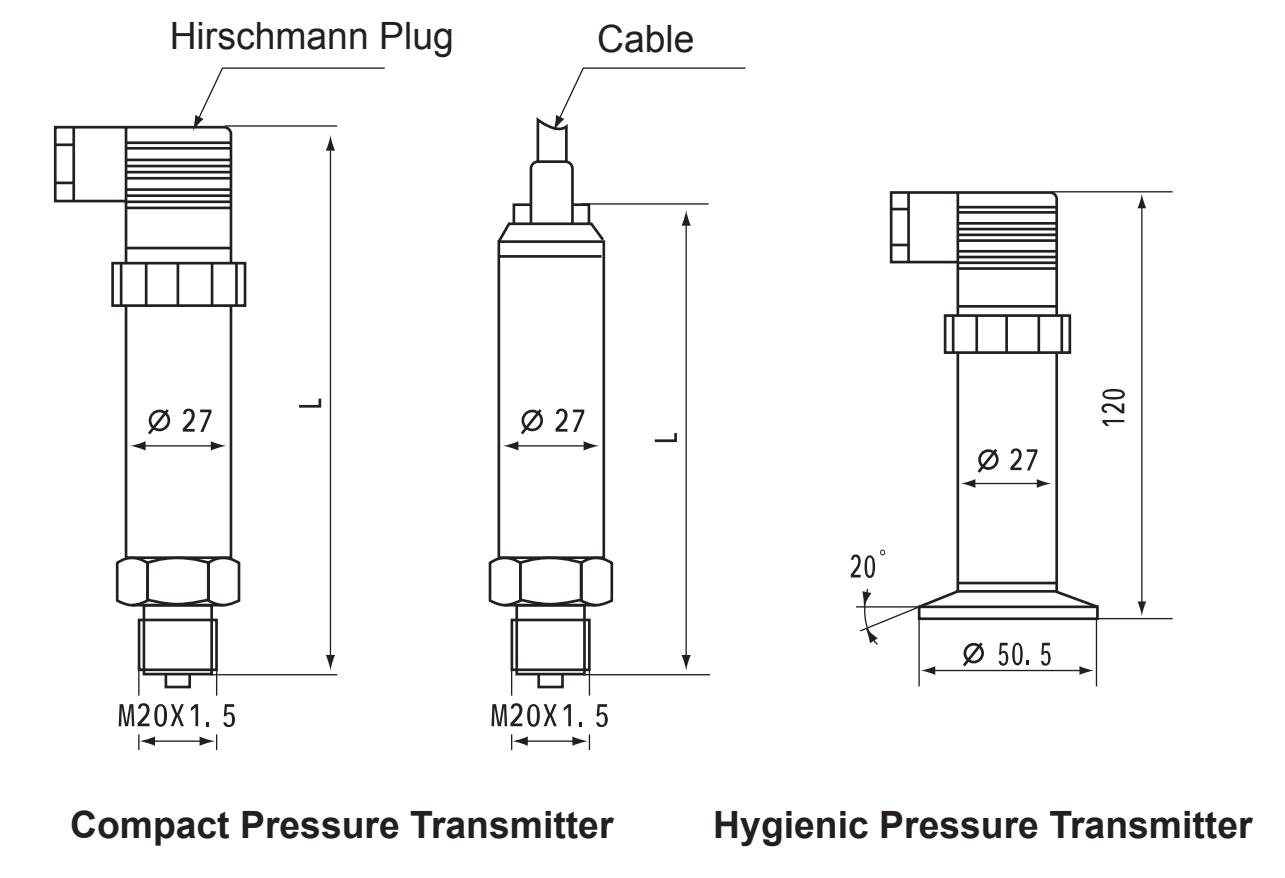

13. Process Connection: M20 × 1.5 Or 1/4npt Or Non-standard

(According To User Needs Processing)

14. Measuring Media: Oil, Water, Gas And Other Media Compatible With 316 Stainless Steel.

15. Protection: Ip65 Pressure Transmitter ; Ip68 Level Transmitter

NOTE:

Avoid installing at ambient vibration and strong electromagnetic interference。

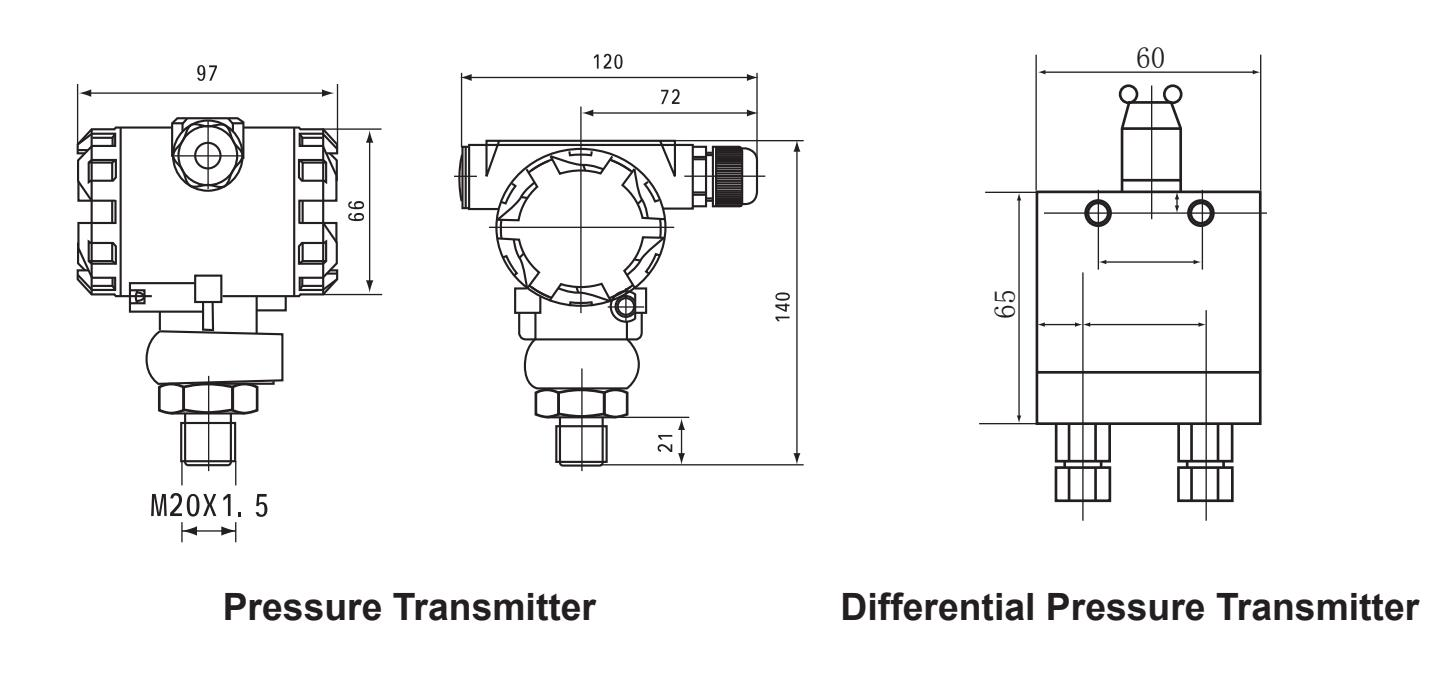

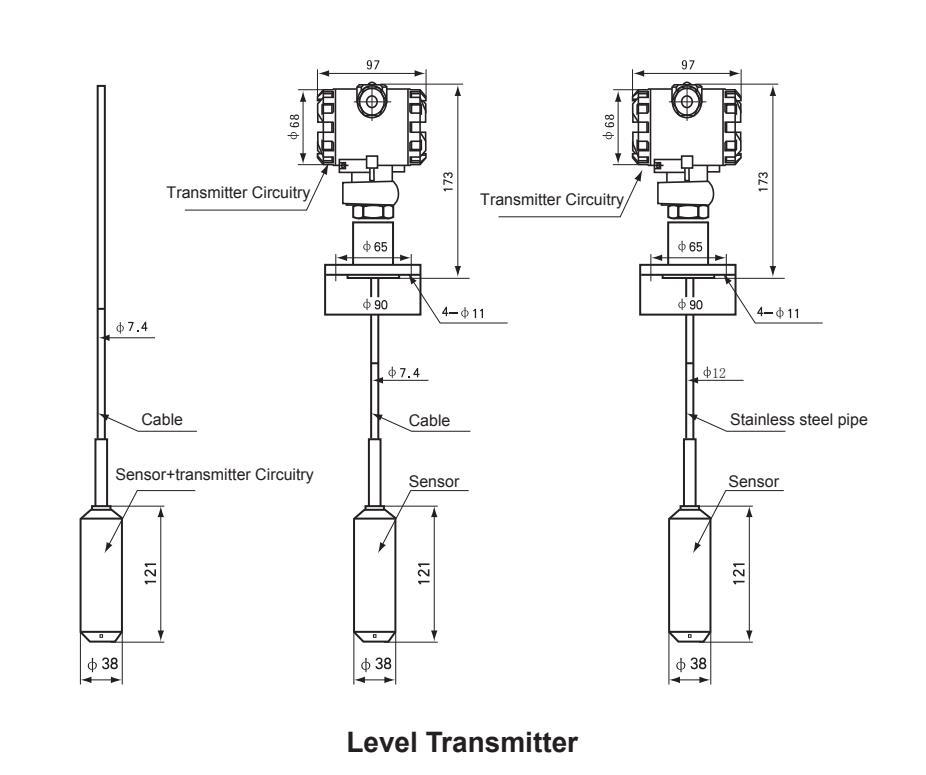

Dimensions:

Installation

1.Pre-installation inspection

( 1) The test pressure must not exceed the upper limit of the measurement range of

the transmitter.

( 2 ) with the measured medium is adapted to the structural material of the transmitter , does not corrode .

( 3 ) whether the measured medium temperature exceeds the operating temperature

range of the transmitter .

2. Installation

( 1 ) pressure transmitter is mounted vertically , can be installed directly on the pipeline pressure test port.

( 2 ) directly into liquid level transmitter can be used , attention fixed firmly to the wire ,moving water installation should take hydrostatic devices.

( 3 ) junction box or the wire connections to take anti-rain treatment .

( 4) The junction box should be grounded .

Note: The transmitter housing with junction box mounting hole size is M6 × 1, 32m

pitch

3. Pressure Transmitter Installation Precautions

(1 ) pressure transmitter pressure interface , the force must be exerted on the lower part of the six-party transmitter , can not be directly screwed the top of the electron shell , so broken inside the transmitter leads.

( 2 ) If there is no standard pressure source user , do not self-adjusting zero and span potentiometers.

( 3 ) If the transient overvoltage or frequent shocks ( such as water hammer , etc. ) in the presence of the pipe or vessel buffer device should be installed to prevent damage to the sensor diaphragm.

4. Level Transmitter Installation Precautions

( 1 ) Note that when you install wire level transmitter in the guide holes to avoid water port , plug and away from the surface , otherwise it will make the transmitter failure and damage.

( 2 ) the action should be let go gently , to prevent the momentum generated when placed between the media and the diaphragm , the diaphragm is damaged . Prohibited by hand or sharp implements poke holes and diaphragm pressure water , do not remove the head guide .

( 3 ) waterproof cable when using air conductivity Do not cut , to prevent media leaks to probe damage to the transmitter .

( 4 ) If there is no standard pressure source user , do not self-adjusting zero and span potentiometers.

( 5 ) In the case split level transmitter wiring should be done well sealed to prevent moisture and corrosive gases from entering .

( 6 ) should be used with protective casing in moving water or particulate media.

(7 ) the measurement medium is acid, alkali, oil , heat and other special media , please specify when ordering.

Scan

QR code on WeChat Follow us

Scan

QR code on WeChat Follow us

24-H hotline+86-536-7393118

Mobile phone+86-19953631088

Copyright (©) 2021 Weifang Aobo Instrument Technology Development Co.,Ltd Address:Building 4C, No. 8009, Minzhu street, Hanting District, Weifang City, Shandong Province (Hanting high tech Industrial Park) Record No:鲁ICP备2020035458号-5