Overview

With the successive promulgation of national incentive policies for "energy saving and environmental protection" and the increasing requirements of residents' heating comfort, unattended heat exchange station control systems have been widely promoted and applied in the central heating industry.

The unattended heat exchange station control system independently developed by our company adopts "advanced smart energy-saving technology" and interlocking protection functions to truly achieve the goal of "system safety, residents' comfort, government satisfaction, and heat company energy saving".

Feature

1. Real-time online

The host computer communicates with each system in real time, and remotely records the internal operating parameters of each heat exchange station;

2. Chain protection

The system can set the alarm parameters and protection parameters of each heat exchange station by itself, and use sound and light to give an alarm;

3. Remote monitoring

The host computer can remotely control and modify the operating parameters of the heat exchange station according to the real-time operating conditions to ensure the normal operation of the heat exchange station

4. Intelligent control

The system can be operated automatically or manually. In special circumstances, the equipment in the station can be operated completely manually without the control system;

5. Quantitative quality adjustment

The system has functions of climate compensator and secondary network adjustment, as well as outdoor temperature and time compensation;

6. Parameter monitoring

The system monitors the relevant parameters of the primary side and the secondary side in real time to ensure the normal operation of the heat exchange station;

7. Data management

The system automatically manages data, calculates statistics, saves, and prints directly based on graphs and tables.

8. Authority management

The control parameters of the controller are completely open, and data exchange is carried out with HMI and SCADA systems through various communication ports. Compatible with various monitoring platforms.

9. Open system

The control parameters of the controller are completely open, data interaction with HMI and SCADA systems through various communication ports, and compatible with various monitoring platforms.

Functions

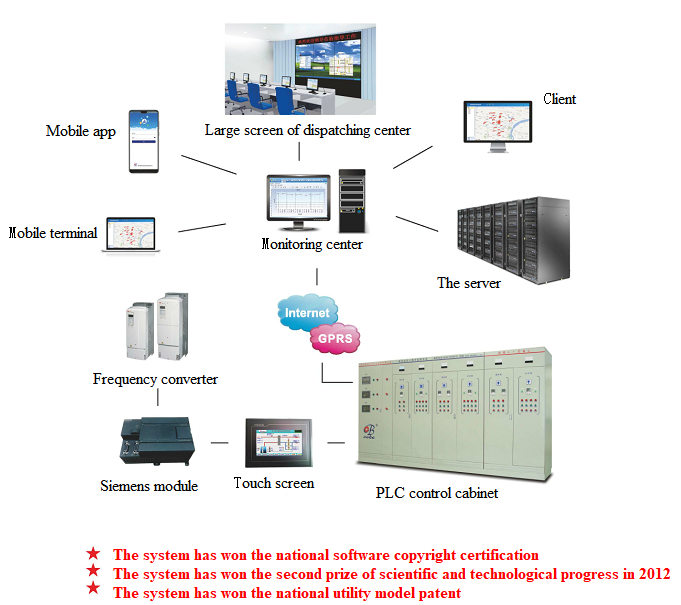

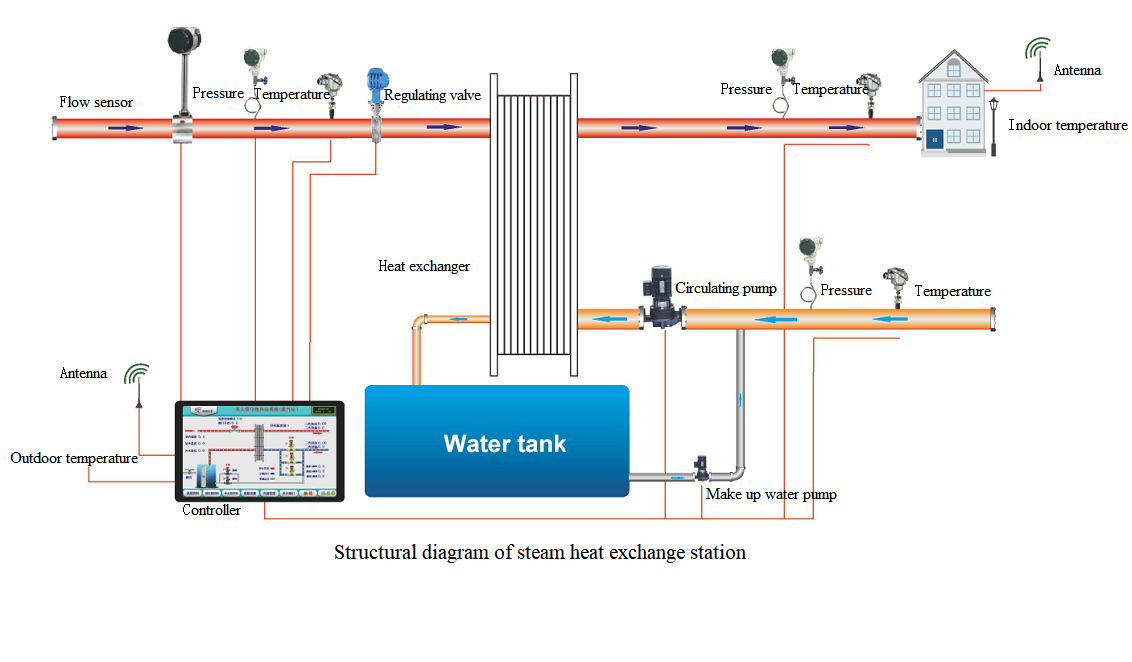

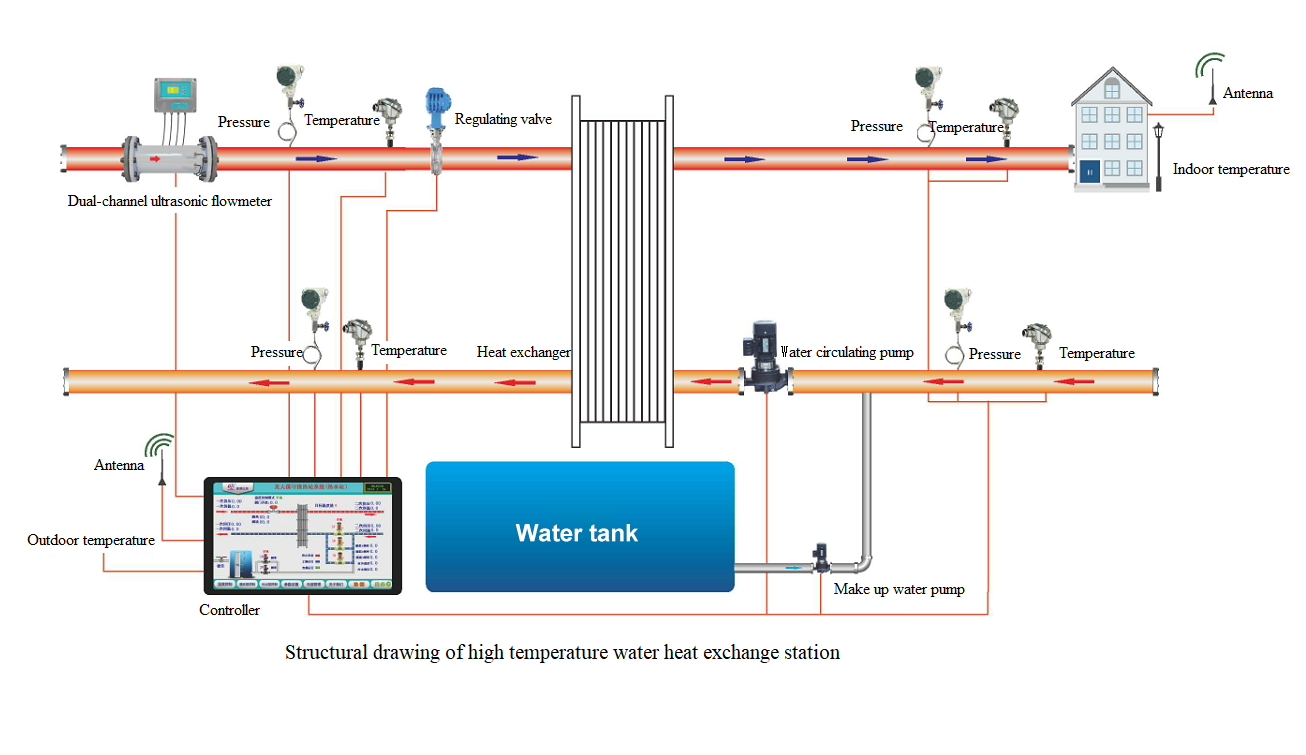

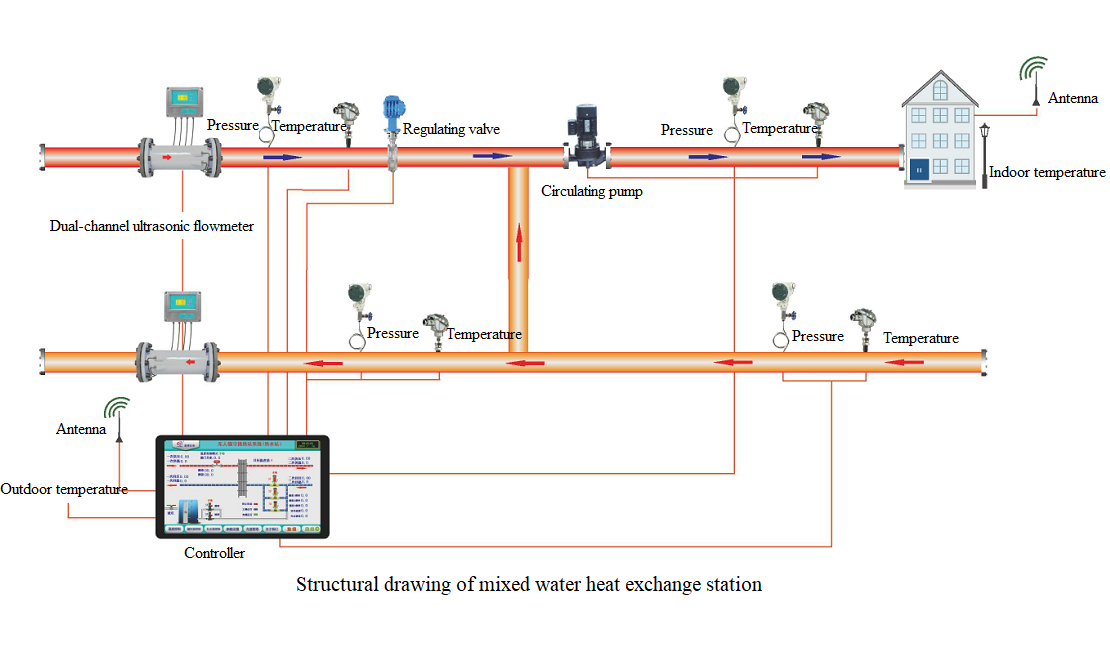

This system is an information management platform that integrates Internet of Things technology, modern computer technology, automatic control technology, communication technology and measurement and control technology, and monitors the heat source, pipe network, and end users of the heating system. The system as a whole realizes the management mode of integrated heat source control, intelligent pipe network monitoring, and end-user information. It can collect, measure, control, remotely transmit, and monitor the primary and secondary networks of the heating network temperature, pressure, flow and other signals. Various parameter states such as temperature, pressure, flow rate, circulating pump, make-up pump operating state and water tank level, etc., can effectively detect and control the heating process. In the actual heating, the temperature of the secondary network's supply and return water is adjusted according to the outdoor temperature, and combined with the residents' room temperature to achieve climate compensation energy-saving control or time-sharing zoned energy-saving control, to achieve the purpose of balance of the whole network, heating on demand, and energy saving.

According to the different needs of the thermal power company, this system can combine technology and functions by itself to provide different solutions. It is not only suitable for the design of the new station's automatic control system, but also for the transformation of the old station; it is not only suitable for steam heating, but also suitable for mixed water and high-temperature water heating.

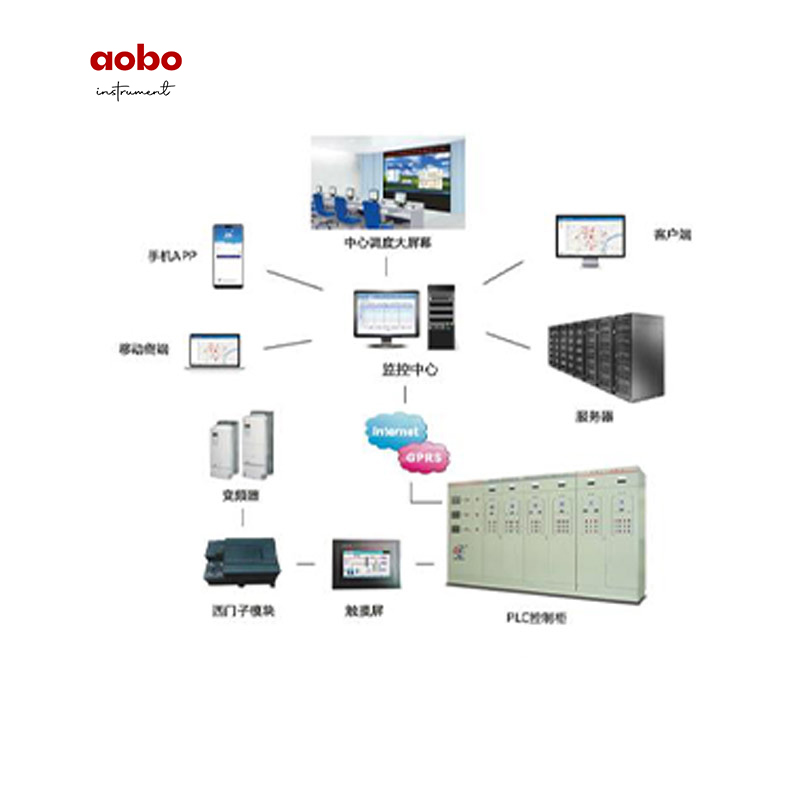

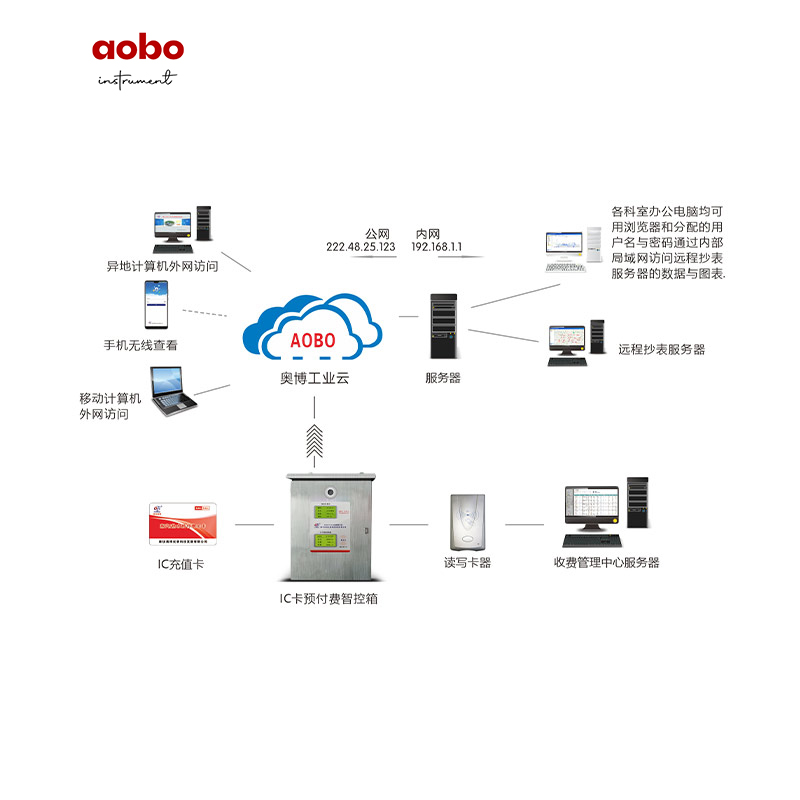

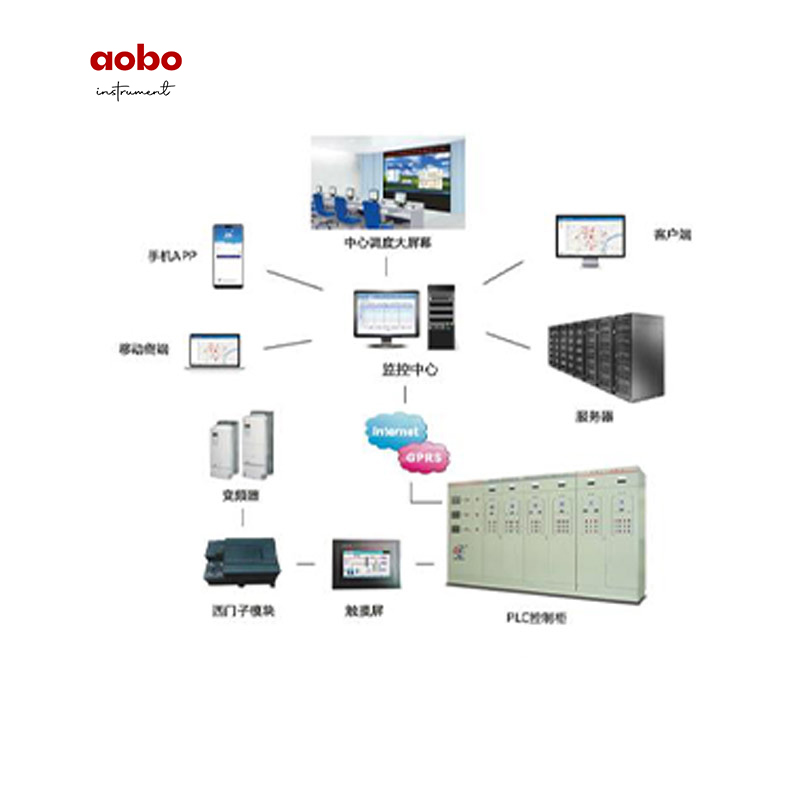

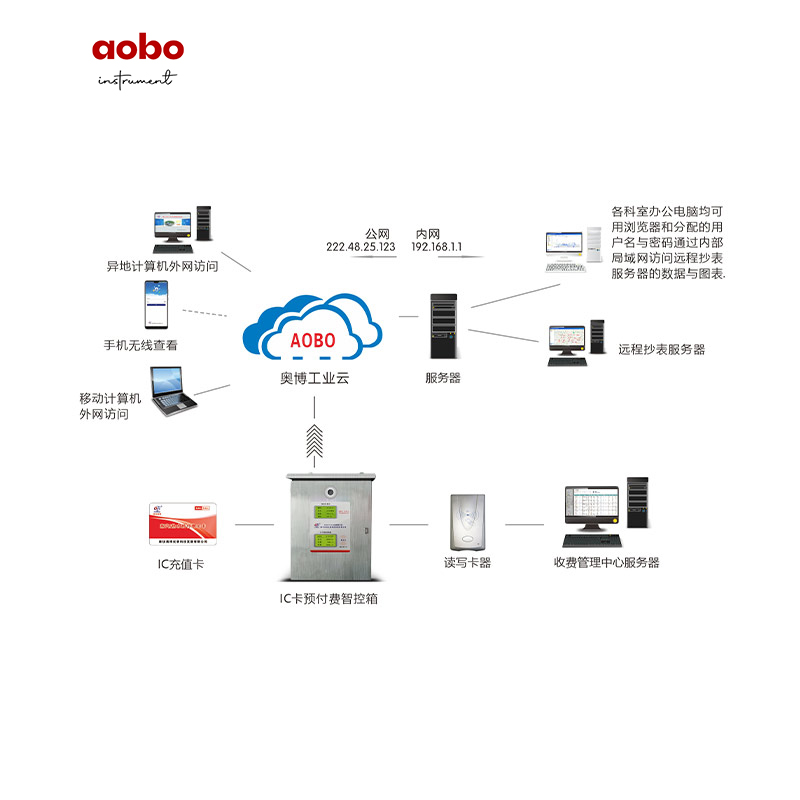

The system information monitoring platform (large-screen dispatch center), PLC control system, system control information upload, system energy-saving control transformation, and terminal residents' room temperature wireless monitoring and control can all be implemented independently.

Heat exchange station control system structure

Advantage

1. Perfect protection mechanism

When the control system of the heat exchange station has an emergency event such as a power failure and a low pressure drop on the secondary side of the network, a shutdown of the circulating pump, the host computer system will immediately sound an alarm, and notify the operator, administrator and inspectors to deal with the problem as soon as possible. The control system automatically stops the system according to the alarm level and closes important dangerous actuators such as valves to avoid major accidents in the station and ensure personal and property safety

2. Complete energy consumption collection and analysis functions

The station control system collects real-time data such as electricity meters, water meters, heat meters, flow meters, temperature, pressure, etc., and transmits them to the upper computer platform in real time. The upper computer system can perform report analysis, curve analysis, and graph analysis on all parameters, allowing the operator With the administrator, the daily energy consumption, monthly energy consumption, and annual energy consumption in the station can be grasped in real time, and the daily energy consumption can be dynamically adjusted and controlled to truly achieve the purpose of energy saving.

3. The screen is simple and easy to operate

The system display interface process is completely designed in accordance with the on-site water conservancy system. The operator can quickly find equipment problems and operating systems through the touch screen flow chart, which greatly reduces the requirements for the operator's level, and anyone can quickly get started.

4. Reliable system stability

The controller adopts Siemens and Schneider brands, and the inverter adopts famous foreign brands such as ABB and Schneider, with long working life and high reliability.

Supporting Module

1.Programmable Controllers

It adopts the programmable controller produced by Siemens, Germany, with its modular structure, easy to realize distributed configuration, high cost performance, strong electromagnetic compatibility, and good vibration and shock resistance. It has become a leader in a wide range of industrial control fields. This is an economical and practical solution. The control module can be selected reasonably according to user requirements and on-site conditions. This product has the following highlights:

Short cycle period and high processing speed

Powerful instruction set can be used for complex functions

Product design is compact and can be used in occasions with limited space

Modular structure, more flexible design

CPU modules with different performance grades are available

Function modules and I/. Module can be selected

Frequency converter

ABB drives are used in industrial fields. The ACS510M series are particularly suitable for fan and water pump drives. Typical applications include constant pressure water supply, heating, cooling fans, subway and tunnel fans, etc. This product has the following highlights:

•Perfect match for fan and water pump applications

•Advanced control panel

• Patented technology for reducing harmonics; variable inductance reactor

•Cycle soft start

•Multi-point U/F curve

• Transcendence Mode

• Built-in RFI filter as a standard configuration, suitable for the first and second environment

• CE certification

3. Temperature sensor

Thermal resistance indexing: Ptwo; PtIOOO;

Thermal resistance grade: A grade: ± (0.15 + 0.002|t|) °C;

Class B: ± (0.30+0,005|t|) °C;

Temperature measurement range: water (0-150) °C; steam (0-550) °C;

Connection mode: external thread M27x2 M16x1.5;

Insertion depth: (100, 150, 200, 250, 300) mm, other specifications can be customized;

4. Wireless data transmission module

The core module produced by the international advanced technology is used to achieve permanent and stable online. The data is transmitted to the monitoring center through the DTU module wireless network' Internet network. It can directly communicate data with remote field sensors through various industrial configuration software, and supports TC P/UDP communication mode, DC (9~24)V (recommended 9~12V) power supply.

Scan

QR code on WeChat Follow us

Scan

QR code on WeChat Follow us

24-H hotline+86-536-7393118

Mobile phone+86-19953631088

Copyright (©) 2021 Weifang Aobo Instrument Technology Development Co.,Ltd Address:Building 4C, No. 8009, Minzhu street, Hanting District, Weifang City, Shandong Province (Hanting high tech Industrial Park) Record No:鲁ICP备2020035458号-5