Overview

Transmitters are widely used in oil pressure equipment, gas equipment, CNC machine tools, central air conditioning, refrigeration equipment, water treatment engineering, environmental protection purification, hydraulic and pneumatic control engineering, automobile, ship, electric power, chemical industry, pharmacy, food and other fields. It is a necessary product for the renewal of old pressure equipment.

Feature

1. digital intelligent chip. Full temperature linear temperature compensation;

2. exquisite structure, compact shape, high cost performance, multiple connection forms:

3. laser welding technology, impact resistance, vibration resistance and stable performance;

4. imported sensors with international advanced technology.

Parameter

1. Output form: 4mA ~ 20mA, (1-5V)

2. Power supply: DC 24V (12V ~ 32V)

3. Accuracy: soil 0.5% □ soil 0.25% □ soil 1%

4. Medium temperature: - 20 ° C ~ 80 ° C

5. Ambient temperature: - 20 ° C ~ 80 ° C

6. Response time: 200ms

7. Load capacity: current type c500q (DC 24V power supply)

8. Repeatability: ± 0.2% f • s

9. Long term stability: ± 0.5% f ・ s / Y

10. Nonlinearity: ± 0.2% f ・ s

11. Temperature compensation range: 0 ° C ~ 60 ° C

12. Overload pressure: 2 times the range

13. Process connection: m20x1.5 or 1 / 4NPT or non-standard (processed according to user requirements)

14. Measuring medium: oil, water, gas and other media compatible with 316 stainless steel.

15. Protection grade: IP65 pressure transmitter

IP68 liquid level transmitter

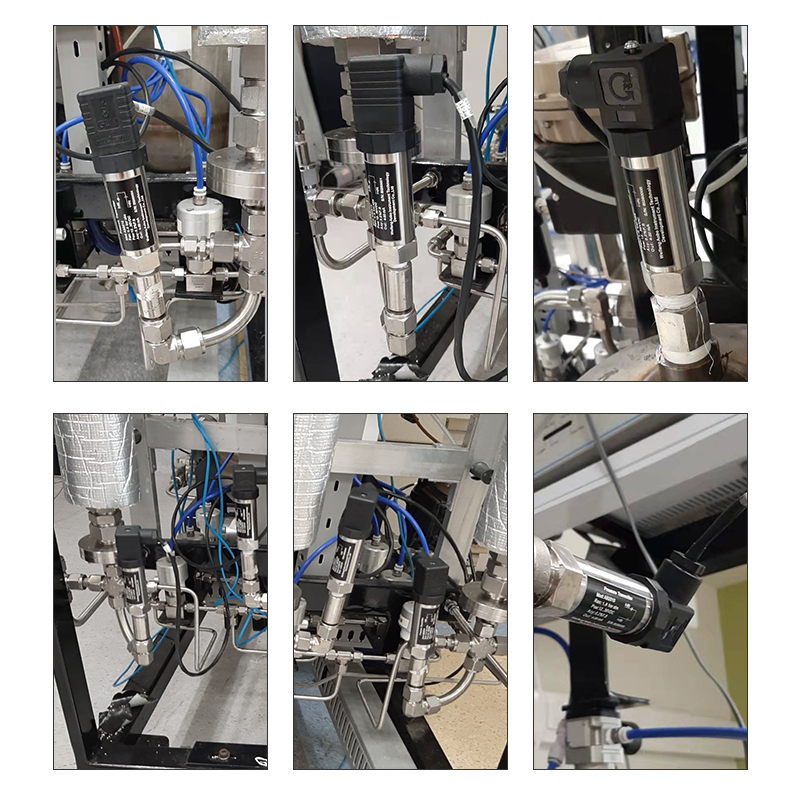

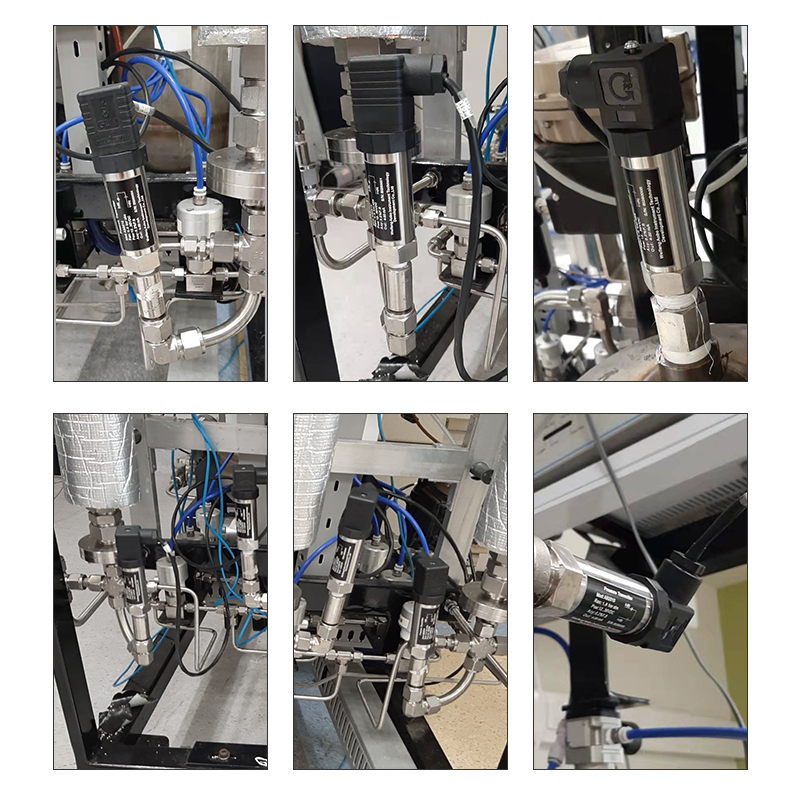

Installation

1. Pre installation inspection

The measured pressure shall not exceed the upper measuring range of the transmitter.

Whether the measured medium is compatible with the structural material of the transmitter and will not be corroded.

Whether the measured medium temperature will exceed the operating temperature range of the transmitter.

2. Installation method

The pressure transmitter is installed vertically and can be directly installed on the pressure interface of the measured pipeline.

The liquid level transmitter can be directly put into use in liquid. Pay attention to fix the conductor firmly. Hydrostatic device shall be adopted for dynamic water installation.

The junction box or wire connection shall be rain proof.

The junction box shall be reliably grounded.

Note: the dimension of mounting and fixing hole of the enclosure with junction box transmitter is M6X1. The hole spacing is 32m

3. Installation precautions

Precautions for installation of pressure transmitter

when connecting the pressure interface of the pressure transmitter, the force must act on the hexagon at the lower part of the transmitter, and the electronic housing at the upper end cannot be screwed directly to avoid breaking the lead in the transmitter.

If the user does not have a standard pressure source, do not adjust the zero and full potentiometer by yourself.

If there is instantaneous overpressure or frequent impact (such as water hammer) in the pipeline or container, a buffer device shall be installed to avoid damaging the sensor diaphragm.

4. precautions for installation of liquid level transmitter

when installing the liquid level transmitter, pay attention to the air guide orifice in the conductor to avoid water 'blockage and stay away from the liquid level, otherwise the transmitter will be invalid and damaged.

When lifting and placing, the action shall be light and slow to prevent the impulse between the medium and the diaphragm from damaging the diaphragm. It is forbidden to poke and press the water inlet hole and its diaphragm with hands or sharp instruments, and the guide head shall not be removed.

Do not cut the waterproof air guide cable during use to prevent the medium from leaking into the probe and damaging the transmitter.

If the user does not have a standard pressure source, do not adjust the zero and full potentiometer by yourself.

The meter of split liquid level transmitter shall be well sealed after wiring to prevent moisture and corrosive gas from entering.

Protective sleeve shall be added when it is used in moving water or medium with particles.

When the measuring medium is acid, alkali, oil, high temperature and other special media, please indicate when ordering.

Scan

QR code on WeChat Follow us

Scan

QR code on WeChat Follow us

24-H hotline+86-536-7393118

Mobile phone+86-19953631088

Copyright (©) 2021 Weifang Aobo Instrument Technology Development Co.,Ltd Address:Building 4C, No. 8009, Minzhu street, Hanting District, Weifang City, Shandong Province (Hanting high tech Industrial Park) Record No:鲁ICP备2020035458号-5